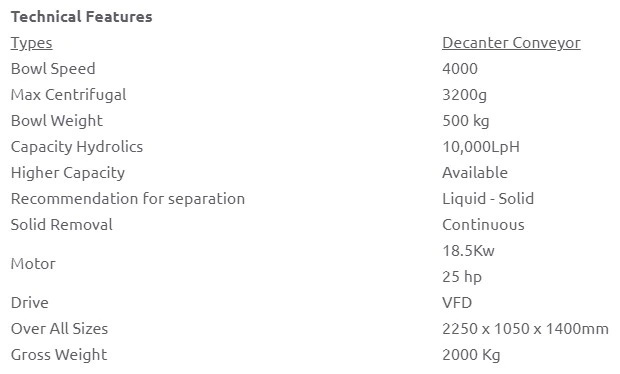

Solid - Liquid Separation

Co-current/Counter Current Design

Separate high percentage of solid-liquid however by the way of mechanical high speed rotation. Mixture feeding the decanter the rotation creates centrifugal force. This is separating different density solid and liquid.

Decanter Centrifuge shall be capable of handling sludge consisting of minimum 1% solids by weight. The dewatered cake shall be based on minimum consistency of 20% to 25% by weight dry solids.

The Inside How Its Work

The decanter's having horizontal rotation bowl, which has a cylindrical and conical section. A scroll is integrated in the bowl. The liquid-solid mixture enters through stationary arranged feed tubes. The solid deposits in the inner bowl wall under the action of centrifugal force. The scroll rotates lower than the bowl speed, conveying the deposits of solid towards conical section. The conical section having solid discharge ports, liquid is also simultaneously separated. The separated liquid flow in the opposite direction and discharged cylindrical ports.

Material of Construction

High quality of stainless steel for all wetted parts and areas. Bowl and scroll are made from centrifugal casting, high strength and corrosion resistant stainless steel.

Rotor Bearing

The special selection and arrangement of bearing provide long life and exceptional reliability a lubrication system supplies either grease or oil to bearing.

Ring dam adjustment

The clarified liquid flow to the cylindrical end the bowl, where they exit over the weir plates is easily adjustable for the precise adjustment of pond depth in the bowl.

Back drive

Torque control assembly

Fixed conveyor rpm

The bowl shell rotates is the same direction as the conveyor but at a slightly higher speed. Conveyor conveying solid of solid discharge ports. Depend on the conveyor speed. The fixed conveyor rpm. As per planetary gearbox ratio. Pinion fixed with torque arm mechanism. The torque control assembly must be set by adjusting the spring adjusting not to trip at the maximum allowable torque, adjustable spring compression link with micro switch. During operation under load conveyor, and planetary gearbox is protected by the torque control mechanism.

Back drive

Countershaft transmission with GS coupling:-

Manual conveyor differential speed.

The dryness of the make can be increased when operating with a lower differential speed by the centrate will be less clear and vice versa, the torque increases while the lower. The differential speed can be changed by the exchangeable pulleys eliminate large of overload, the GS coupling disengages from planetary gearbox pinion, adjustable spring link with micro switch. During operation under load conveyor and planetary gearbox is protected by the GS coupling overload mechanism.

Back drive

Eddy current back drive

Automatic conveyor speed mechanism

The eddy current break system is to make it possible to automatically change the conveyor speed. with control systems.

The gearbox pinion shaft is attached with eddy current brake through flexible coupling. The stationery field oil is energized is set magnetic flux, through eddy current resist rotary creating the breaking effect. As per required of conveyor speed the control adjusted breaking speeds, the torque is controlled by photo cell mechanism. Trip the breaking currents. During the operation under load conveyor and planetary gearbox is protected by over load electronic mechanism.